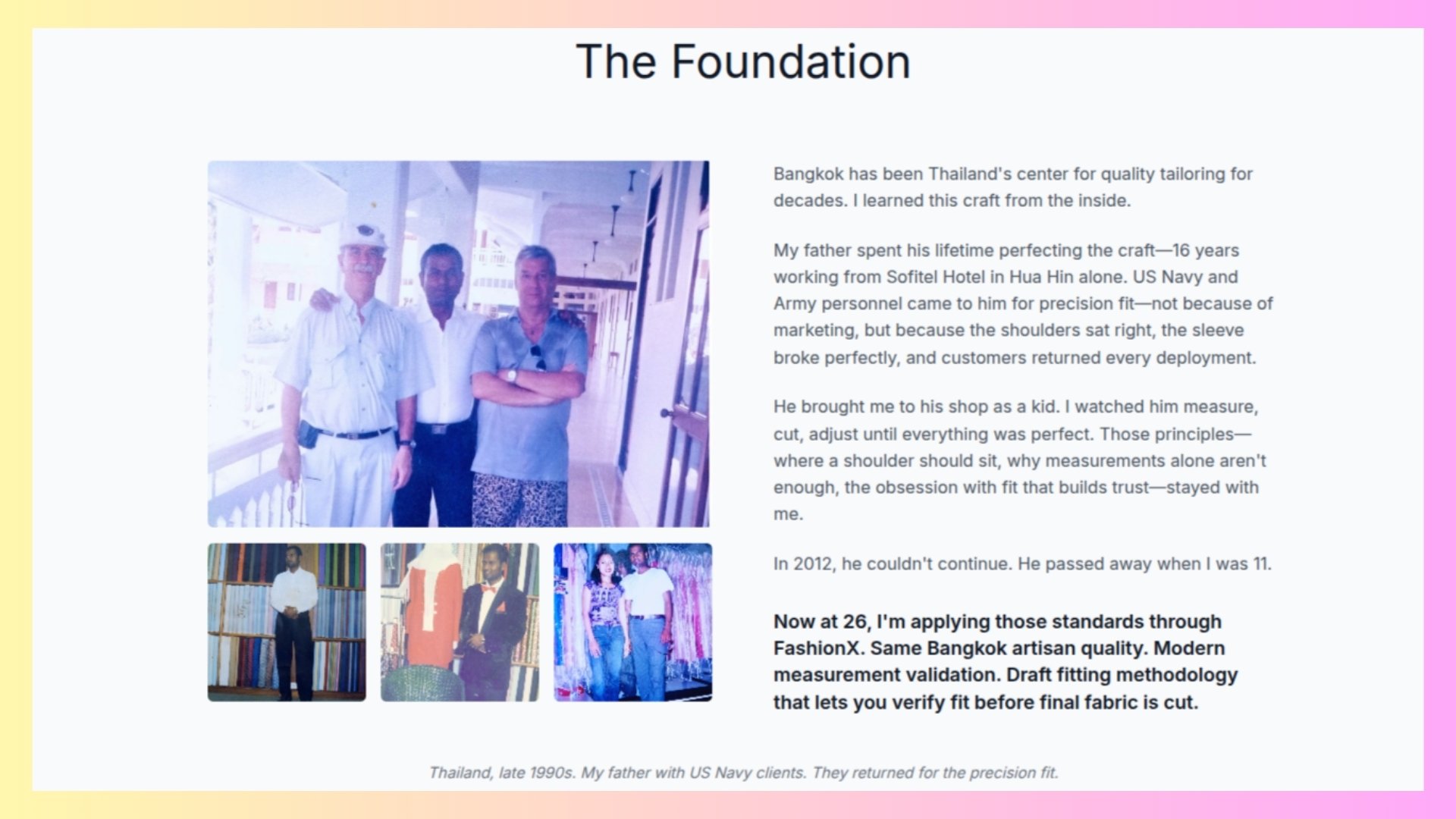

US Navy officers used to dock in Thailand for R&R. Some went to the beaches. Some went to the bars. The ones who cared about how they looked went to my father.

He worked at the Sofitel Hotel in Hua Hin—16 years at that one location alone. But he'd spent his entire life as a tailor before that. The Sofitel years were just the ones I remember.

Word spread ship to ship. Officers would arrive with names written on paper: "Ask for this guy. He'll get it right." They'd come back every deployment, sometimes with friends, sometimes with new measurements because they'd bulked up or slimmed down between tours.

It wasn't because he was cheap. Bangkok tailors have always been affordable. They came back because the fit was perfect—and it was perfect every single time.

What Made Them Return

My father understood something most tailors miss: Western bodies are different.

Thai tailors trained on Thai clients often struggle with broader shoulders, longer torsos, the proportions that American and European men carry. My father had spent decades fitting foreigners. He knew where the fabric needed to give, where it needed to hold, how a jacket should drape on someone six inches taller than his average local customer.

But technique wasn't the whole story.

He checked twice. Always. Before cutting final fabric, he'd create a test version first—what we now call a draft fitting. The officer would try it on, my father would make notes, and only then would he cut the good fabric.

This was before I knew there was a name for it. To me, it was just how he worked. No guessing. No hoping. Verify the fit, then commit.

What I Learned Watching Him Work

I was a kid in the shop. I'd sit in the corner doing homework while he measured customers, pinned fabric, made adjustments too subtle for me to understand at the time.

What I absorbed wasn't technique—I wasn't trained as a tailor. What I absorbed was the standard.

Precision isn't about speed. It's about not accepting "close enough." A shoulder that sits 5mm off will bug the customer forever, even if he can't articulate why. A sleeve that breaks wrong will make him tug at his jacket all day. These details matter.

My father didn't rush. He didn't cut corners. He didn't promise delivery times he couldn't keep just to close a sale.

He passed away in 2012. I was eleven.

Why This Matters for You

I'm not a tailor. I don't pretend to be. What I am is someone who grew up watching what "right" looks like—and who refuses to accept less.

LinenSuit.shop works with master tailors in Bangkok who trained in the same tradition my father practiced. The techniques haven't changed because they didn't need to. Hand-stitched canvas construction. Floating chest pieces. Sleeves set to match natural arm hang. The things that separate a proper suit from a fused, mass-produced jacket.

The draft fitting process—the thing my father did instinctively—is now standard on every order. Before we cut your CAVANI linen or John & Taylor tweed, you try a test garment at home. You tell us what needs adjusting. We fix the pattern. Only then do we commit to your final fabric.

Learn exactly how draft fitting works.

It's the same process Savile Row tailors charge $3,000+ for. We do it for $590-800 because Bangkok costs are different—not because the craftsmanship is.

The Standards Haven't Changed

My father cared about two things: fit and durability. The suit had to sit right on day one, and it had to sit right on day one thousand.

We source from the same European mills that supply high-end tailors worldwide. CAVANI from Italy. DRAGO for premium wool. VBC—the world's oldest wool mill, operating since 1663. John & Taylor for English tweed.

See our complete fabric range.

The materials are the same. The techniques are the same. The difference is logistics: we ship worldwide instead of waiting for you to visit Bangkok.

Though if you do visit Bangkok, we still offer hotel service—three visits, measured in person, suits delivered before you fly home. 5-8 days. It's the closest thing to how my father worked.

Pattern Storage: Your Fit, Forever

Here's something my father couldn't offer: digital permanence.

When you order from us, we don't just make your suit and forget you exist. We store your pattern. Your exact measurements, your specific adjustments, your proven fit—saved in your profile forever.

Next time you need a suit, a blazer, trousers, shirts—we already know how to build them for your body. No new measurements required. No new draft unless your body has changed.

One perfect fit, reorders for life.

This Isn't Just Business

I could have done something else. I have skills in other areas. Building LinenSuit.shop wasn't the obvious path.

But every time I see a customer email saying the suit fits perfectly—that it's the first time something off a website actually worked—I think about my father measuring Navy officers in that hotel shop.

He'd understand what we're doing here. Different tools, same principle: don't guess, verify. Don't rush, get it right. Don't accept "close enough" when precision is possible.

This is his legacy, adapted for a world where customers can't always fly to Bangkok. The standards are the same. The care is the same. The results are the same.

Just delivered to your door instead of your hotel room.

Experience the Difference

If you've been burned by online tailoring before—if you've received suits that didn't fit, that looked nothing like the photos, that made you swear off custom forever—I understand the hesitation.

All I can tell you is: we're not like that.

We send the draft first. We verify before we cut. We store your pattern so next time is even easier.

Same process my father used. Same results those Navy officers kept coming back for.

Learn how draft fitting protects your investment →